How to Select Pipe Floats: Calculating the Required Quantity (Sorfan Guide)

Choosing the right pipe floats for pipelines is essential for safe and stable operation on water. Properly selected floats for hydrotransport keep the pipeline at the surface and—most importantly—ensure buoyancy even if the pipe becomes blocked. In this guide, we explain a simple method to calculate the required number of pipe floats and share practical ordering tips.

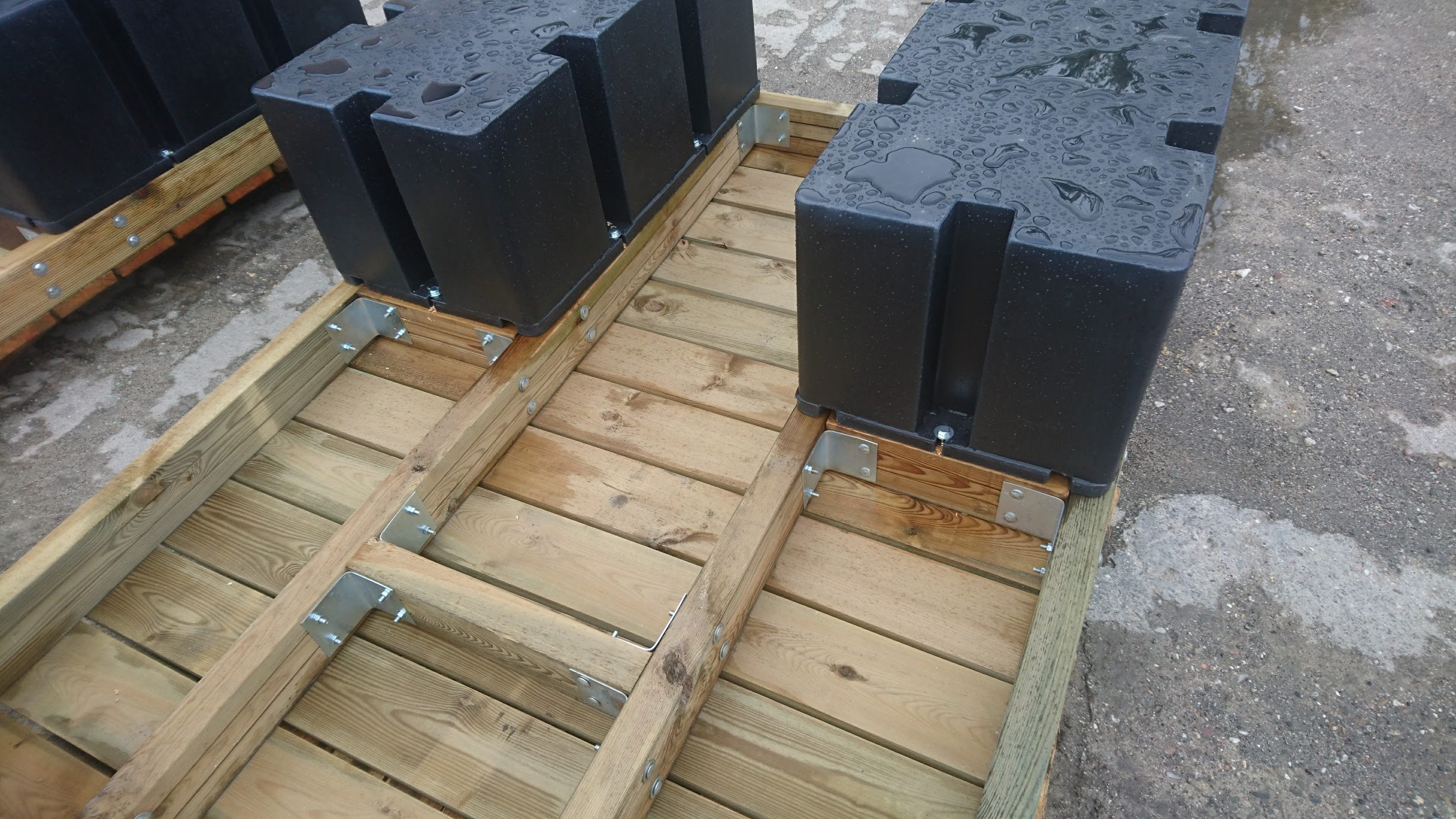

Sorfan – European Manufacturer of UV-Resistant Polyethylene Pipe Floats

Sorfan is a European manufacturer of pipe floats designed for floating pipelines and hydrotransport applications. Our floats are made from polyethylene that is:

-

weather resistant

-

UV resistant

As standard, we supply galvanized bolts with our pipe floats. On request, we can provide stainless steel bolts (additional cost).

Sorfan pipe floats are suitable for pipelines made of:

-

polyethylene (PE) pipes

-

steel pipes

What Are Pipe Floats Used For?

Pipe floats have two key functions:

-

Keeping the pipeline on the water surface during normal operation.

-

Maintaining buoyancy when the pipe is blocked—this is the most critical scenario, because the pipeline can become heavier and lose flotation stability.

In most projects, pipes are supplied in 12 m lengths and then connected into longer sections. That is why our recommendations are based on a 12 m pipe section.

How Many Pipe Floats Do You Need? Minimum Guideline per 12 m Pipe

Sorfan minimum recommendations (please follow)

The size of our floats is designed to meet the above requirements when using at least:

-

min. 5 pipe floats per 12 m PE pipe

-

min. 6 pipe floats per 12 m steel pipe

Please follow these recommendations.

Step-by-Step: How to Calculate the Total Quantity of Pipe Floats

Step 1: Calculate how many 12 m pipes you have

Number of pipes = total pipeline length (m) / 12

Step 2: Multiply by the minimum floats per pipe

-

PE pipeline: Total floats = number of pipes × 5

-

Steel pipeline: Total floats = number of pipes × 6

Example (PE, 240 m):

240 / 12 = 20 pipes → 20 × 5 = 100 pipe floats

Example (steel, 240 m):

240 / 12 = 20 pipes → 20 × 6 = 120 pipe floats

Tip: For demanding conditions (waves, current, extra fittings, bends), adding a small reserve is a smart practice.

IMPORTANT: Float Diameter Refers to the Pipe Outside Diameter (OD)

A common ordering mistake is mixing OD with another dimension.

IMPORTANT – the float diameter refers to the outside diameter of the pipe.

Please verify the pipe OD before placing an order.

Non-standard pipe or cable diameter?

If your pipe/cable diameter differs from the standard sizes we offer, contact us. We have proven methods for adapting non-standard diameters to Sorfan hydrotransport floats.

Most Popular Pipe Float Sizes

The most frequently sold Sorfan pipe floats are:

-

Pipe float 110 mm

-

Pipe float 160 mm

-

Pipe float 225 mm

-

Pipe float 280 mm

-

Pipe float 315 mm

We also offer:

-

one of the widest ranges of hole diameters for pipes and cables,

-

a unique product: a float with 3 holes (available on the market only from us).

Standard Orange Color + Custom Colors Available

We produce pipe floats in orange as standard. This is a warning color and is highly visible on water.

Custom colors are available on request. Minimum order: 30 pcs.

Hollow vs. Filled Floats: Our Approach + Optional PUR Filling

Sorfan pipe floats are hollow inside. In our view, any float—also one filled with EPS/polystyrene—should be removed and repaired or replaced after damage. Therefore, we do not see the need to fill floats as standard.

Optional closed-cell PUR foam filling (special request)

We can fill floats with closed-cell polyurethane (PUR) foam:

-

minimum order: 10 floats

-

lead time: approx. +14 days, because the filling is performed by an external partner.

Fast Production and Delivery in Europe

We are likely among the fastest in Europe when it comes to manufacturing and delivering the required quantity of pipe floats—especially for time-sensitive projects.

Custom Pipe Floats: Different Shape or Size

We can also produce floats in custom shapes or sizes. If you need a tailored solution for a specific pipeline or cable application, contact us—we’ll help you choose the best option.