How to Build a Floating Dock Using Sorfan Floats?

A floating dock is a functional and aesthetic solution, ideal for lakes, ponds, and rivers. Thanks to modern polyethylene floats, it is possible to build a stable, durable, and safe structure tailored to individual user needs. Below we explain step by step how to design and build a floating dock using Sorfan floats.

What Are Sorfan Floats Used For?

Sorfan floats are designed to support floating structures made of:

-

wood,

-

composite materials,

-

steel,

-

aluminum.

They are suitable for both recreational docks and utility platforms, such as those used for mooring boats, kayaks, or other watercraft.

Standard float dimensions (length × width × height):

-

100 × 50 × 30 cm

-

100 × 50 × 42 cm

-

100 × 50 × 60 cm

-

100 × 100 × 42 cm

-

120 × 100 × 73 cm

The last dimension—the float height—is crucial for buoyancy and determines how high the dock sits above the water surface.

How to Choose the Right Number and Type of Floats?

To ensure stability and user comfort, three key questions must be answered:

1. What is the weight of the floating platform?

Estimate the weight of:

-

the load-bearing structure,

-

the deck surface (e.g. wooden boards or composite decking).

2. What additional load is expected?

Consider:

-

the number of people using the dock at the same time,

-

additional equipment such as benches, tables, railings, ladders, etc.

3. How high should the dock be above the water?

A lower dock is preferred if:

-

users frequently enter the water,

-

kayaks or SUP boards are used.

A higher dock is recommended when:

-

high waves occur and water splashing onto the deck should be avoided,

-

larger boats are moored and comfortable boarding is important.

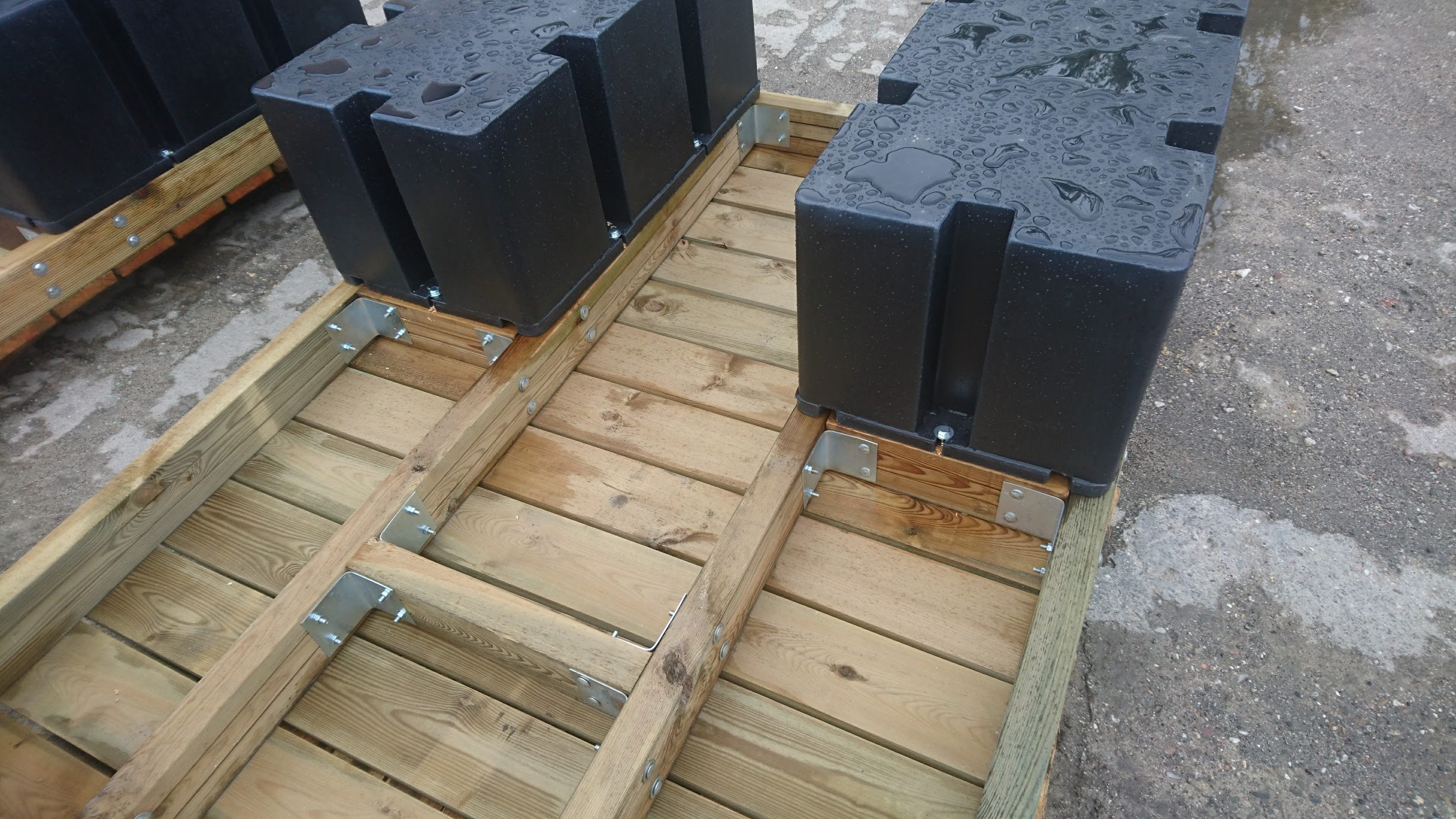

Installing the Floats to the Dock Structure

Sorfan floats are made of durable, weather-resistant polyethylene. Mounting slots are located along the upper edges of the floats:

-

slot width: 12 mm,

-

recommended bolt/screw diameter: 8–10 mm,

-

large washers are recommended for better load distribution.

The floats are fixed from below by passing bolts or screws through the slots into the structural beams. The beams should be spaced 50–100 cm apart to ensure secure and stable mounting.

Dock Width and Stability

Based on our experience, a floating dock should be no narrower than 150 cm. This width provides sufficient stability, safety, and comfort during use.

Access Ramp from Shore

To allow dry and safe access from the shore to the floating dock, an access ramp is required. Its length depends on the shape and slope of the bottom.

If the bottom slope is gentle, a longer ramp should be used to prevent the dock from resting on the ground. Keep in mind that a long ramp adds extra load to one side of the dock. In such cases, we recommend:

-

installing an additional float under the dock on the ramp side, or

-

if possible, placing a float directly under the ramp.

Float Color and Filling Options

Sorfan floats are manufactured as standard in black, as dirt and stains are least visible in this color.

Other colors are available on request.

The floats are hollow. In our opinion, any float—whether filled with EPS or polystyrene—should be removed and repaired or replaced if damaged. Therefore, we do not consider standard filling necessary.

On special request, the floats can be filled with closed-cell polyurethane (PUR) foam.

The minimum order quantity for this option is 10 units.

Custom Float Solutions from Sorfan

In addition to standard models, we also manufacture floats:

-

in custom shapes,

-

with non-standard dimensions,

-

tailored to specific floating dock or platform projects.

If you are planning to build a floating dock and need assistance selecting the right floats, contact us — we will be happy to help you design the optimal solution.